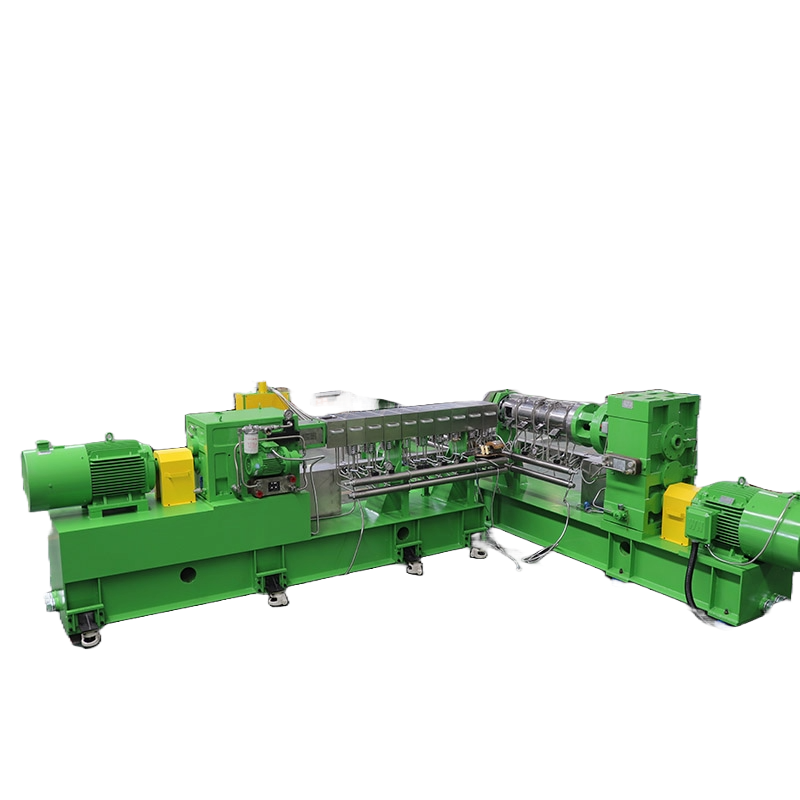

PET foam extrusion production line

- Production process: It usually includes steps such as raw material transportation, melting, foaming, and extrusion molding.

- Material adaptability: It can handle various PET raw materials to produce foamed products with different properties.

- Product features: The produced PET foamed materials have excellent characteristics such as light weight, heat insulation, and sound insulation.

- PRODUCT DETAILS

The characteristics and advantages about the PET foaming extrusion production line is as follows:

- Production process: It usually includes steps such as raw material transportation, melting, foaming, and extrusion molding.

- Material adaptability: It can handle various PET raw materials to produce foamed products with different properties.

- Product features: The produced PET foamed materials have excellent characteristics such as light weight, heat insulation, and sound insulation.

- Control system: It adopts advanced control technology to ensure the stable operation of the production line and the quality of the products.

- Customization: The configuration and parameters of the production line can be customized according to the needs of customers.

- Capacity and efficiency: The capacity of different models of production lines is different, which can meet the production needs of different scales.

- Energy saving and environmental protection: It has a high energy utilization efficiency and reduces the impact on the environment.

- Degree of automation: It can realize automated production, improve production efficiency, and reduce labor costs.

- Quality inspection: It is equipped with quality inspection equipment to ensure that the products meet the relevant standards.

- Maintenance: It needs to be maintained regularly to ensure the long-term stable operation of the production line.