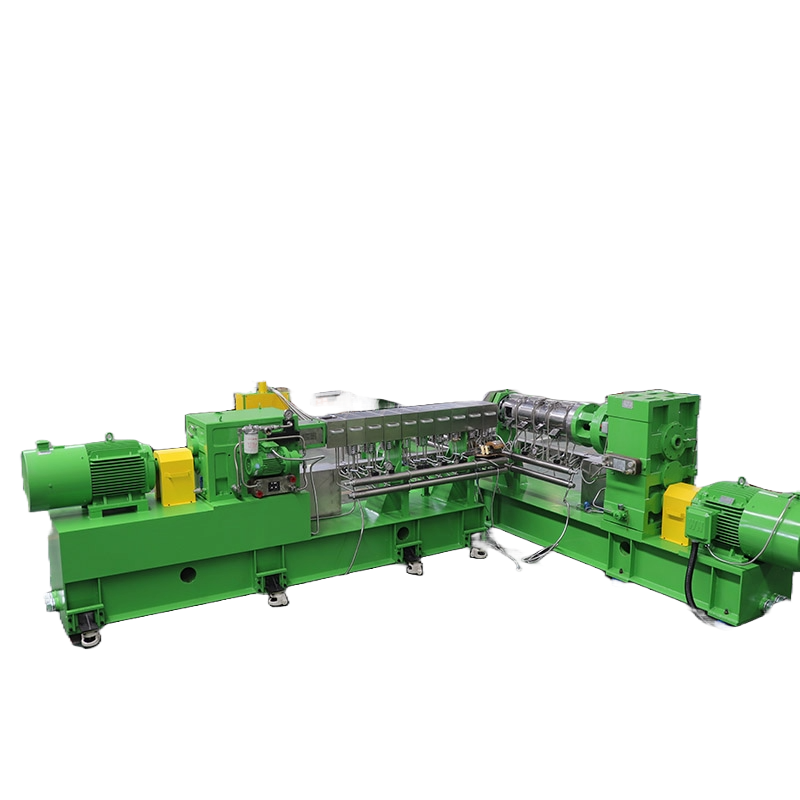

PLA foaming production line

- The PLA foaming extrusion production line is a specialized line for producing PLA (polylactic acid) foaming materials. Here is an overview of this production line:

- Raw material feeding: The PLA raw materials are fed into the production line.

- Melting and extrusion: The PLA is melted and extruded through heating.

- PRODUCT DETAILS

Introduction to the PLA foaming extrusion production line.

- The PLA foaming extrusion production line is a specialized line for producing PLA (polylactic acid) foaming materials. Here is an overview of this production line:

- Raw material feeding: The PLA raw materials are fed into the production line.

- Melting and extrusion: The PLA is melted and extruded through heating.

- Foaming process: Special techniques are employed to create bubbles in the melted PLA, resulting in the foaming effect.

- Cooling and shaping: The foamed PLA is cooled and shaped into the final product.

- Control system: An advanced control system is used to precisely control various process parameters.

Features of the produced materials include:

- -Light weight but high strength.

- -Good thermal and insulation properties.

- -Degradable, with excellent environmental friendliness.

Advantages of the production line include:

- -High degree of automation for increased production efficiency.

- -Ability to customize product specifications according to requirements.

- -Energy-efficient and environmentally friendly production process.

Applications of the produced materials cover:

- -Packaging field, such as cushioning materials.

- -Building sector, such as insulation materials.